Driving the development of Australia’s green steel industry for a sustainable future.

Forging a greener future.

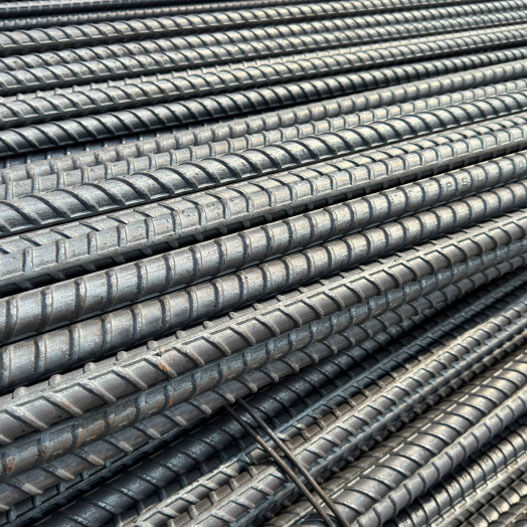

Our mission is to build sovereign capability in advanced green steel manufacturing through the construction of Australia’s first steel mill in 30 years. By driving South-East Queensland’s circular economy, we can produce low emissions reinforcing bar to support a sustainable construction industry. Our commitment to cost-competitive, reliable rebar proves that going green requires zero compromise on quality.

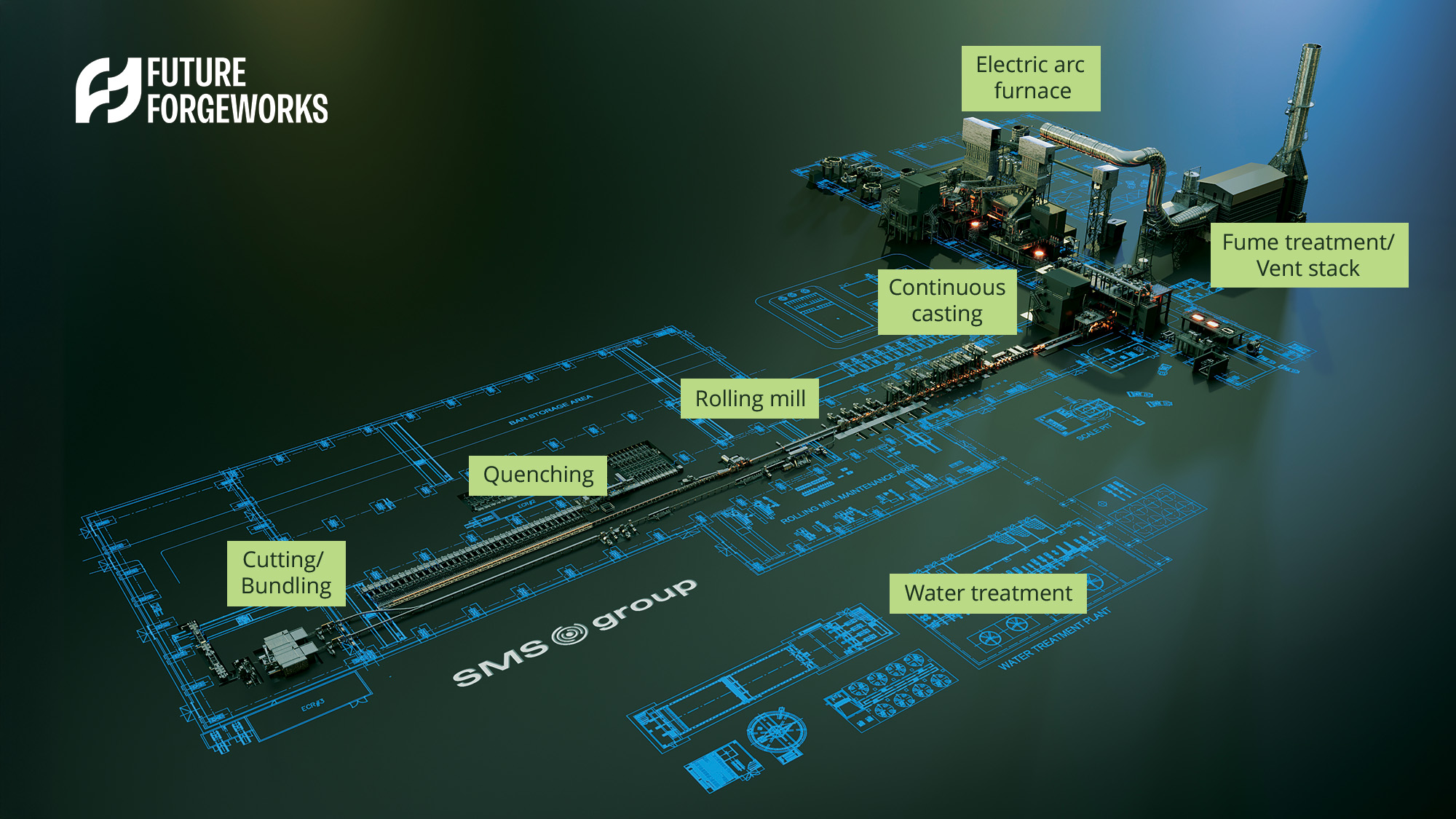

We’re bringing state-of-the-art Industry 4.0 technology to the steel manufacturing process. Powered by an electric arc furnace and continuous mill technology, our Swanbank Green Steel Mill will be the greenest, safest and most cost-efficient production route for long steel products in Australia.

While driving South-East Queensland’s circular economy, we will strengthen the local supply chain with our commercial partners and help abate the global impact of heavy industry.

By positioning the Ipswich region as the centre for excellence in manufacturing technology, we aim to forge a legacy of innovation, responsibility and opportunity to become an employer of choice.

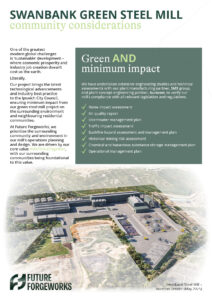

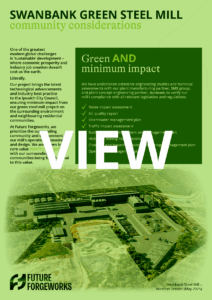

One of the greatest modern global challenges is ‘sustainable’ development, where economic progress doesn’t cost us the earth – Literally.

With a minimum impact mill powered by renewable energy, and economic stewardship by an experienced leadership team, we will rise above the challenge to lead the shift towards sustainable industry and meet the next generation’s demand for green construction materials.

With an ambitious 2027 first steel goal, we hope to boost Queensland’s manufacturing sector in time for the Brisbane 2032 Olympic and Paralympic Games infrastructure delivery.

Our partnership and connection with local communities, commercial partners and policy makers underpins our conviction in success that matters.

Our commitment to sustainability extends beyond the natural environment, with economic benefit and long-term employment opportunities for the people of Ipswich and broader South-East Queensland a key priority.

We’re not just building a mill for today; we’re building for the next generation of Queenslanders.

Swanbank Green Steel Mill

Our SMS group CMT350® mill design features an electric arc furnace and continuous mill technology, producing 350,000 tonnes of reinforcing bar and coil per year from the heart of Swanbank’s industrial precinct.

Feasibility studies and technical assessments have been completed and our steel mill project has received statutory approvals through the Ipswich City Council and the Queensland Government.

Civil works will commence in early 2026.

Making rebar from South-East Queensland’s circular economy

At Future Forgeworks, our goal is to provide sustainable construction materials that help businesses meet tomorrow’s environmental expectations. Recycling steel reduces energy consumption by up to 74% and generates fewer air and water pollutants than primary steel production. Australia’s natural resources are conserved for the next generation by minimising water usage and land disturbances.

Heavy melting steel (HMS 1) and scrap metal, destined for the overseas market, will be collected, sorted and processed by our recycled steel partners to become furnace ready.

Queensland’s abundant wind and solar resources will contribute to the transformation of scrap metal into green rebar through the steel mill’s electric arc furnace.

Using our low-emissions steel mill technology, metallurgists will remove impurities and contaminants and add alloys to meet our high quality standards. Steel slag will be provided to our partners who reuse this byproduct for asphalt, further reducing our ecological footprint.

We will utilise an endless casting and rolling process to optimise energy consumption, lowering both transformation costs and emissions.

Our rebar and ribbed reinforcing wire will be utilised by Queensland builders to reinforce concrete, ensuring building structures last for generations to come.

In time, scrap metal, rebar and heavy melting steel from demolition sites will also be collected and processed by our renewable steel partners to become furnace ready, closing the loop on the circular economy, while minimising our embodied carbon footprint.

Our leadership team

Our leadership team is comprised of seasoned executives with significant experience in global engineering, project leadership and infrastructure development.

At Future Forgeworks, we prioritise the surrounding community and environment in our mill’s operations planning and design. Our commitment to sustainability extends beyond the environment, creating commercial growth and employment opportunities for the people of Ipswich and surrounding communities.

After completing extensive technical assessments, our development application was lodged with the Ipswich City Council. Approval was received in November 2025.